This story was originally published by UNC Media Hub. Story by Kaitlyn Schmidt, Video by Olivia Mundorf, Photography by Andrew Lewis, Graphics by Isabelle DeCamillis

Turning the corner into the main floor of the Thomas Built Buses Manufacturing Plant, a long chalkboard-painted wall with hundreds of signatures reads:

The Best Darn People… BD3

For employees at Thomas, BD3 means three things: Best Darn People, Best Darn Bus and Best Darn Values.

As one of the leading North American manufacturers of buses, Thomas looks to use values to guide its construction and everyday work life. After all, the company is tasked with no small feat, producing 500,000 of the vehicles on the road yearly that transport about 26 million kids to and from school every day.

“If you think about it, the student’s day starts and ends on the school bus,” Mario DiFoggio, manager of direct sales and marketing, said. “The purpose of what we do from a day in, day out standpoint is so critical to society.”

It’s no secret why Thomas Built has won a “World Class” Net Promoter Score — a scale in which customers rate companies 0-10 on how likely they’d recommend them to a friend — for the eighth year in a row. Building a quality product that is safe, green and long-lasting is Thomas’ bread and butter, as it churns out some of the most innovative vehicles in North America in the heart of North Carolina.

Best darn bus

High Point has been home to Thomas Built Buses for more than 100 years. In 1916, when car designer Perley A. Thomas lost his job in wartime layoffs, he founded Perley A. Thomas Car Works, focused on renovating and building streetcars.

With car and bus transportation on the rise in the 1930s, Thomas pivoted to manufacturing school buses and, by the 1960s, became known nationwide for the distinctive yellow vehicles. In 1972, the company was renamed to Thomas Built Buses to reflect its growth as one of the country’s top school bus manufacturers.

The company is a subsidiary of Daimler Truck North America LLC, the leading commercial vehicle manufacturer in North America, and has an average annual revenue of $550 million.

The Saf-T-Liner C2 Manufacturing Plant located in High Point was added in 2004 on a 90-acre plot of land. It has 275,000 square feet of production space split between body assembly, paint shop, trim line, chassis prep and final assembly areas.

So, how exactly is a school bus made?

As the largest supplier to itself, the plant makes and molds all of its metal parts at its High Point facilities, which are shaped, welded and riveted in the ¾ of a mile-long main body assembly line. Above each station in the line is a television monitor that tracks the 14- minute rotation time — after the time’s up, the employees rotate to a new bus.

The body of the bus is painted, sent to the trim line to be outfitted with interior features like flooring, insulation, lights, windows and seats, then attached to its chassis, the structural underframe that includes the engine, transmission, driver’s seat, steering wheel and wheels.

When it’s finally all put together, the vehicle is tested and inspected in the final assembly line before being driven out to the lot.

In total, the plant generates about 40 buses daily, seven days a week, which are shipped across the 50 states, Canadian provinces, and even to U.S. territories like Guam. Because of various climates and terrains, every state and school district requires distinct regulations for their buses. Thus, there are over 20,000 customizable options, which might include anywhere from a white roof to a black hood to reflective tape. For perspective, the leading manufacturer car brand only has about 285 total customizable options.

“These things are not vanilla,” DiFoggio said.

For customers, each vehicle costs roughly $100,000, and Thomas’ electric school buses can cost up to three times that price tag. In a school district, the average lifetime of a bus is about 15 years, and Thomas elongates this process through higher efficiency rates and lower operational costs.

The company implements a Selective Catalytic Reduction system, which reduces tailpipe emissions, and high-quality engines and transmissions to improve fuel efficiency. If parts of the bus need to be replaced, Thomas offers a variety of parts and technicians trained in warranty work.

Best darn values

School buses are the largest form of public transportation worldwide, and the vehicles are the most heavily regulated on the road. The build and design of Thomas buses exceed the 42 rigorous Federal Motor Vehicle Safety Standards.

Because most accidents involving school buses occur when students get on and off, Thomas’ pedestrian detection system alerts drivers of people maneuvering around the bus. Auto-reversing doors detect pressure if something is caught in the door and open it back up, alerting the driver of the obstruction.

For crash safety, collision warning signals warn the driver and electronic stability control keeps the bus upright. In addition, 360-degree cameras monitor the activity inside and outside of the vehicle — a rearview mirror with a backup camera and side-view turn angles is an add-on option for some models.

In accordance with the Clean School Bus Program, the EPA’s $5 billion effort to electrify school buses, Thomas is in the process of perfecting fully electric vehicles. It has partnered with electric solutions manufacturer Proterra to construct a battery system that sustains its most popular C2 model, called the Saf-T-Liner C2 Jouley.

This vehicle won N.C. Chamber’s inaugural “Coolest Thing Made in NC” contest in 2020 as the pinnacle for green technology in the state.

The battery-powered buses can drive about 135-140 nominal range miles, making them the perfect “use case” for developing the technology. For a shorter route of 40 miles, for example, a bus can drive its morning route, charge for a few hours, then get back on the road for its afternoon route.

“Never before has a school bus been in the forefront of technology like this,” DiFoggio said.

Along with eliminating emissions, electric buses also lack that familiar hum that diesel engine buses have… The C2 Jouley is quiet.

“Noise begets noise,” DiFoggio said. “So with a much quieter vehicle, the unintended consequence is that the children are much more quiet.”

There are around 300 of these C2 Jouleys in circulation, unique by the blue Thomas logo on the front and sides, which are still being tested daily for more regular use.

Best darn people

The employees interviewed for this story have been with the company 39, 42, 49 and 50 years.

Why do Thomas’ 1,800 employees stick with the company for such long tenures? Well, the money, $47,893 annual salaries on average, and benefits like healthcare, 401K plans and vacation time are certainly a draw. But it’s the camaraderie that has built the Thomas family — even some blood relatives that work there together — allowing the plant to operate seamlessly 24/7.

“Everybody looks after one another,” account management specialist Steve Riley said. “You can count on just about anybody from any kind of department. So cross-functionality is very strong here at Thomas.”

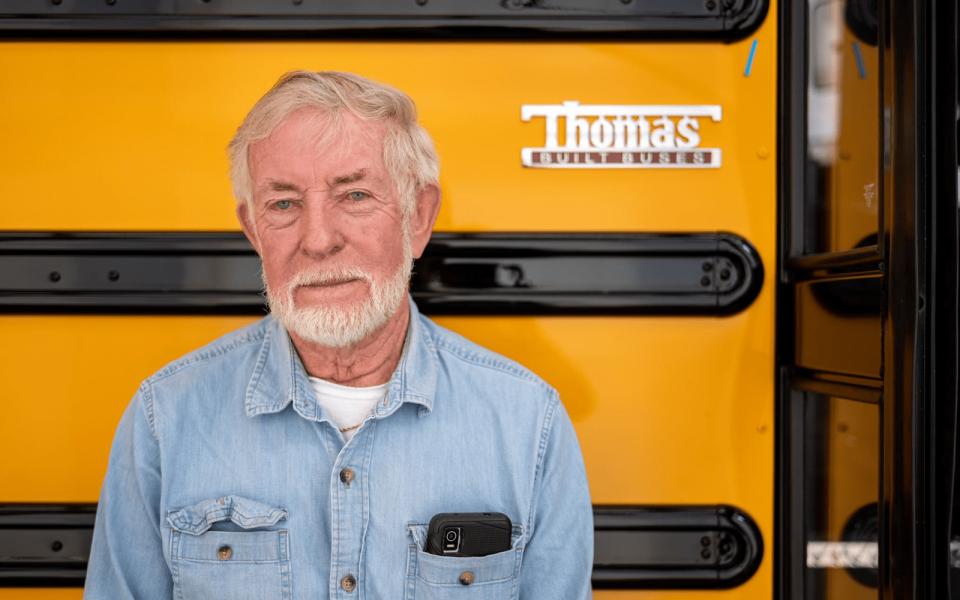

Charlie Irwin started with Thomas in 1991 and has done every role from basic parts to welding to warranty work. He’s at the plant seven days a week, volunteering when he’s not on the clock. When asked why he puts in the overtime work, he simply responded:

“It’s just a feeling inside of me. I mean, I just, I love what I do. And if the doors are open, I’m here.”

When a big yellow vehicle comes barreling down the local North Carolina streets, almost immediately the employees recognize the signature Thomas features and logo. The product instills a very specific feeling in them.

“Pride,” Riley said. “It makes me think that there’s kids on that bus and they’re likely going to make it to school and they’re gonna be safe.”

Summertime is the busy period for Thomas, and DiFoggio says that even in the monotony of the dog days, the company’s purpose is emphasized in each task done by every employee: building these vehicles for our future.

“When these vehicles go off the line, you know that they’re purpose-built for something. And it’s bigger than all of us,” DiFoggio said. “If we don’t believe in what we do, then we don’t build a quality product. So we have to believe in the purpose of what we provide every day.”

Join the First Amendment Society, a membership that goes directly to funding TCB‘s newsroom.

We believe that reporting can save the world.

The TCB First Amendment Society recognizes the vital role of a free, unfettered press with a bundling of local experiences designed to build community, and unique engagements with our newsroom that will help you understand, and shape, local journalism’s critical role in uplifting the people in our cities.

All revenue goes directly into the newsroom as reporters’ salaries and freelance commissions.

Leave a Reply